Product Description:

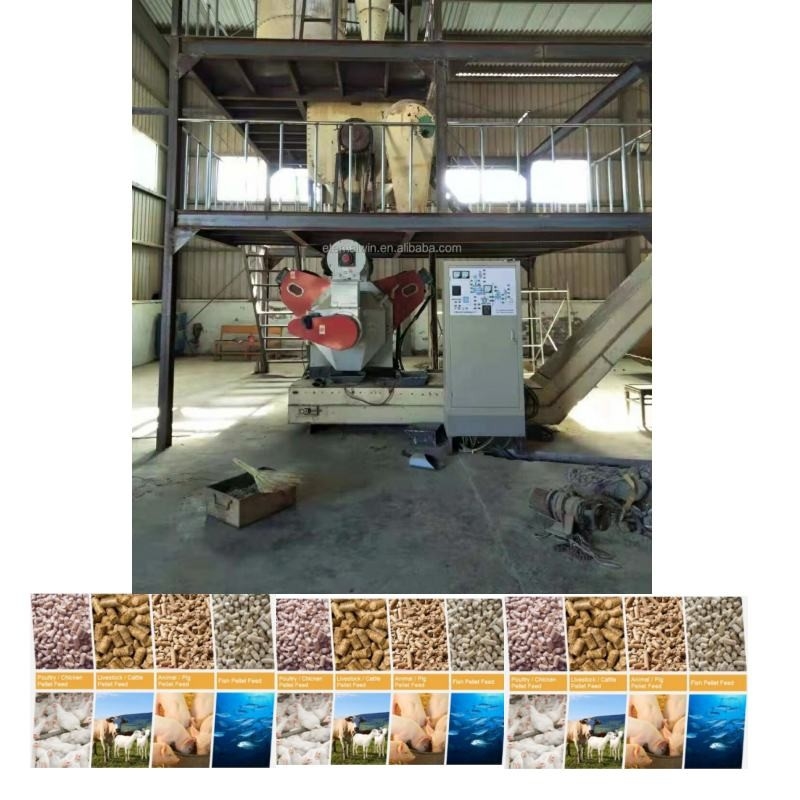

The Animal Feed Pellet Production Line is a comprehensive solution for producing high-quality animal feed pellets efficiently. This advanced system is designed to meet the needs of modern animal feed production facilities, offering a complete set of equipment for processing raw materials into finished pellets.

With a packing system that includes an Automatic Bagging Machine, this Animal Feed Pellet Making Line ensures convenient and automated packaging of the final product. The machine is capable of efficiently bagging the pellets, streamlining the packaging process and enhancing overall operational efficiency.

Measuring 17*5*5.5m in dimensions, the Animal Feed Production System is compact and space-efficient, making it suitable for installation in various facility layouts. Its versatile size allows for easy integration into existing production setups, maximizing space utilization and operational flexibility.

Installation of the Animal Feed Production Line is supported by an Engineer Guide, ensuring a smooth and hassle-free setup process. The guide provides comprehensive instructions and assistance to facilitate the installation of the equipment, enabling quick deployment and minimizing downtime.

Operating on a power supply of 380V/50Hz/3Phase, this Animal Feed Pellet Production Line is designed for high-performance and reliable operation. The power supply specifications are optimized for efficient energy utilization, reducing operational costs and enhancing overall production efficiency.

The final pellet size produced by the Animal Feed Production System ranges from 1mm to 12mm, offering versatility in pellet specifications to meet various animal feed requirements. Whether producing pellets for small or large animals, the system can deliver consistent pellet sizes for optimal feeding results.

Applications:

Zhongdebao Animal Feed Pellet Production Line is a high-quality product designed for efficient production of pellet feed for animals. With models with different capacity, the production facility is suitable for various application occasions and scenarios.

Originating from China, this feed pellet production system is certified by CE, SGS, and BV, ensuring its quality and reliability. The minimum order quantity is one set, and the price is negotiable, making it accessible to a wide range of customers.

The packaging details include wooden package and full container shipment, guaranteeing the safe delivery of the product. With a delivery time of 15-20 days and flexible payment terms such as T/T and Western Union, customers can expect a smooth purchasing process.

With a supply ability of 1000 units per month and a capacity range of 1-20t/h, this Animal Feed Pellet Production Line is suitable for small to large-scale operations. The final pellet size ranges from 1-12mm, meeting different animal feeding requirements.

Engineers are available to provide after-sales service overseas, ensuring the smooth operation of the feed pellet machine. The high pellet quality produced by this system makes it ideal for various animals, including poultry, livestock, and aquaculture.

Overall, Zhongdebao Animal Feed Pellet Production Line is a reliable and efficient solution for producing high-quality animal feed pellets. Whether for small farms or large feed production facilities, this system offers the capabilities and performance needed for successful animal feeding operations.

Support and Services:

The Product Technical Support and Services for the Animal Feed Pellet Production Line include:

- Installation assistance for setting up the production line.

- Training sessions for operation and maintenance of the equipment.

- Troubleshooting guidance for any issues that may arise during operation.

- Regular maintenance and servicing to ensure optimal performance.

- Technical documentation and manuals for reference.

If you are interested in our products, please contact me without hesitation!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!